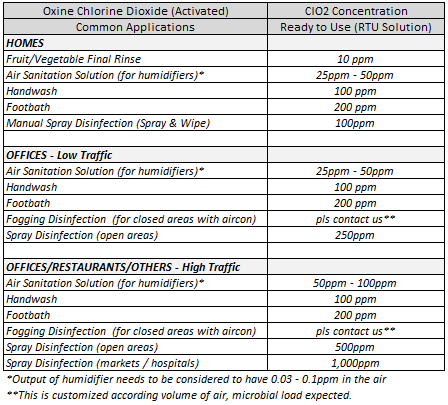

APPLICATIONS / DOSAGES

OXINE is manufactured in the USA and is shipped for export in a stable concentrate form with 2% (20,000ppm) Chlorine Dioxide (ClO2) available for generation. To relase ClO2, Oxine (20,000ppm) needs to be 'activated'. This is done by adding 3% food grade citric or food grade phosphoric acid to the concentrate prior to any dilution. Activation releases the available chorine dioxide gas for fast acting disinfection. Activated chlorine dioxide is about 4X more potent than stable/unactivated chlorine dioxide.

Upon activation, Oxine (20,000ppm) is then diluted to the RTU (Ready-To-Use) solutions depending on the ppm ClO2 concentrations required for specific applications. Below is a general applications-dosage chart.

Preparation for 4 liters of RTU-500 solution.

(Note: Activation of Oxine must be done on the day of use, and should be done in an open (or ventilated) area.

1. Get 100ml of Oxine concentrate (20,000ppm).

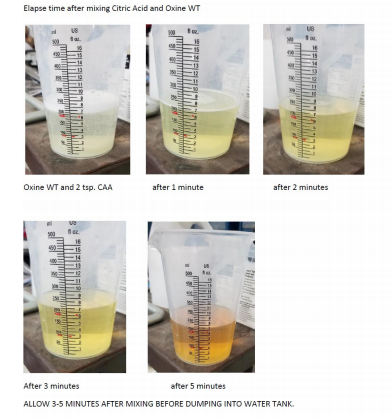

2. Add 3ml phos. acid. Allow 5 mins. to react.

3. Dilute 1 --> 40. This can be done by preparing 3.9liters of water in advance.

4. Add 100ml Activated Oxine (20,000ppm) to 3.9 liters of water to make 4 liters (RTU-500ppm).

3. Seal container properly.